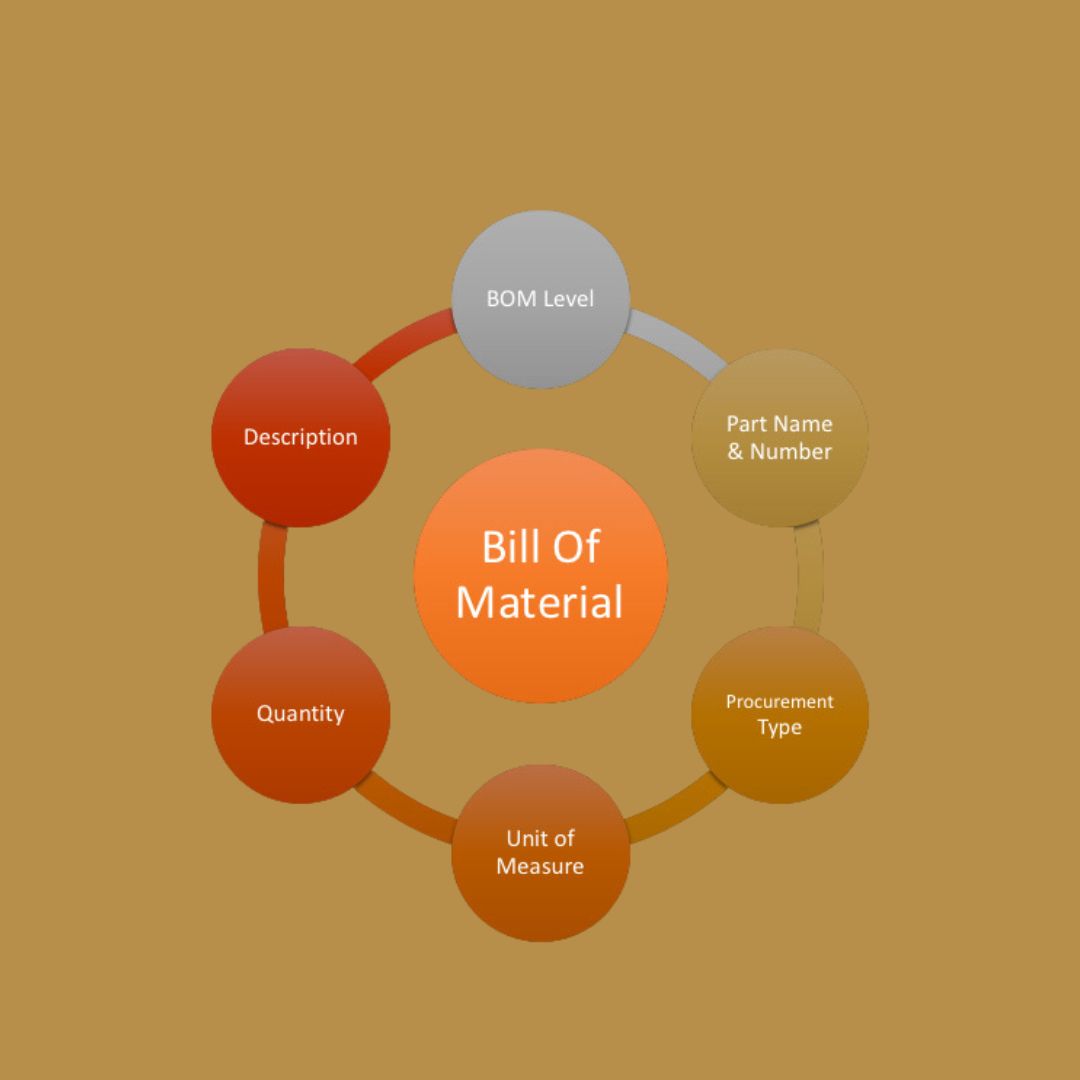

The lifeblood of any manufacturing operation is the smooth flow of materials. At the heart of this flow lies the bill of materials (BOM). A BOM is a detailed list of all the parts, components, and raw materials required to produce a finished product. It serves as the recipe for your manufacturing process, ensuring you have everything you need, in the right quantities, at the right time.

Why is a Bill of Materials Important?

An accurate and well-managed BOM offers a multitude of benefits:

- Improved Efficiency: Having a clear picture of your material needs allows for optimized production planning and scheduling.

- Reduced Costs: By identifying potential material waste and redundancies, BOMs help control inventory costs.

- Enhanced Quality: A BOM ensures all necessary components are included, reducing the risk of errors and improving product quality.

- Streamlined Communication: A BOM serves as a common reference point for all stakeholders involved in the manufacturing process.

Beyond the Basics: Bill of Materials Management Software

While a simple spreadsheet can be used for basic BOMs, managing complex products with numerous parts and sub-assemblies necessitates a more robust solution. This is where bill of materials management software comes in.

BOM Software Features and Benefits

BOM software offers a variety of features to streamline your manufacturing processes:

- Centralized BOM Management: Create, store, and manage all your BOMs in one secure location.

- Version Control: Track changes made to BOMs, ensuring everyone is working with the latest version.

- Integration with Other Systems: Seamlessly integrate your BOM software with your ERP, CAD, and inventory management systems.

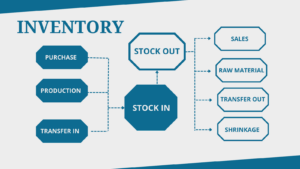

- Real-Time Inventory Tracking: Gain real-time visibility into your material stock levels to avoid stockouts and production delays.

- Costing and Pricing: Generate accurate cost estimates based on real-time material costs.

Bill of Materials Templates and Software: A Winning Combination

Many BOM software solutions offer pre-built templates to get you started quickly. These templates can be customized to fit your specific needs, saving you time and effort.

Raw Material Inventory Management:

Effective BOM management goes hand-in-hand with raw material inventory management. By having a clear understanding of your material requirements (thanks to your BOM!), you can optimize your inventory levels, reducing storage costs and the risk of obsolescence.

Conclusion

A well-defined bill of materials is the foundation for efficient and cost-effective manufacturing. By leveraging BOM management software and effective inventory management practices, you can streamline your operations, improve product quality, and gain a significant competitive edge.